Filter

Super Magnets

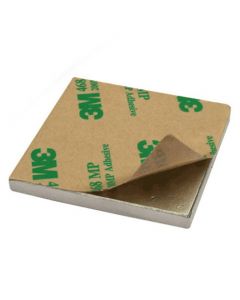

Super Magnets encompass several families of rare-earth magnets. Super Strong Neodymium Magnets are primarily made with the alloy of neodymium, iron, and boron (NdFeB). Buy the strongest neodymium magnets here. Disc, blocks, rings and spheres in various sizes, as sets & self-adhesive. The World's Strongest & Most Powerful Rare Earth Magnets. We carry a large inventory of permanent magnets; neodymium, ceramic, samarium cobalt, & alnico magnets available from stock for immediate shipment in a wide range of shapes, sizes & grades.

12 Article variants

-

Immediately available

£20.14incl. Tax excl. shpipping Shipping

-

Immediately available

£0.37incl. Tax excl. shpipping Shipping

-

Immediately available

£0.41incl. Tax excl. shpipping Shipping

-

Immediately available

£0.54incl. Tax excl. shpipping Shipping

-

Immediately available

£0.40incl. Tax excl. shpipping Shipping

-

Immediately available

£0.40incl. Tax excl. shpipping Shipping

-

Immediately available

£0.41incl. Tax excl. shpipping Shipping

-

Immediately available

£0.89incl. Tax excl. shpipping Shipping

-

Immediately available

£0.60incl. Tax excl. shpipping Shipping

-

Immediately available

£0.40incl. Tax excl. shpipping Shipping

-

Immediately available

£0.68incl. Tax excl. shpipping Shipping

-

Immediately available

£1.38incl. Tax excl. shpipping Shipping

Super Magnets / Rare Earth Magnets / Strong Neodymium Magnets

Neodymium magnet, is the most powerful permanent magnet. It is widely used in all kinds of motors, electronic component, automatic equipment, new energy vehicle, artificial intelligence, mobile phone and medical device, etc.

We offer strong Neodymium magnets for sale which are the most popular Strong Rare Earth Magnets in the World. The alloy of three elements NdFeB (Neodymium, Iron, and Boron) joined together creates these strong Neodymium Magnets. People use the term “Rare Earth Magnet” and “neodymium magnet” synonymously because neodymium magnets are the most popular and well-known of the rare earth group for sale today. Other common names for strong neodymium magnets include Neo Magnets, or Earth Magnets.

Super Strong Neodymium Magnet, buy the strongest neodymium magnets here Disc, blocks, rings and spheres in various sizes, as sets & self-adhesive. The World's Strongest Most Powerful Rare Earth Magnets.

Neodymium Magnets from Magnosphere

Neodymium Iron Boron (“Neo”, NdFeB or Neodymium) Magnets are made from an alloy containing, amongst others, the elements Neodymium, Iron and Boron (NdFeB). The NdFeB magnets are the strongest type of magnet commercially available and are manufactured in a wide range of shapes, sizes and grades. We offer 53 grades of licensed standard corrosion resistance Neodymium Iron Boron and now an additional 72 grades of improved corrosion resistance Neodymium Iron Boron, each type with 30 types of coating finish for each grade (125 grades in total with 34 finishes – 4250 combinations).

The NdFeB magnets are anisotropic sintered magnets – the alloy is jet milled to a fine powder and is then compacted in the presence of a magnetic field to give it a preferred direction of magnetisation. The NdFeB magnets are then sintered to fuse the powder together before final machining and magnetising produces the completed super strength Neodymium magnet.

The Neodymium magnets are also known as Neo magnets, Neodymium Iron Boron magnets, Neodymium-Iron-Boron magnets, Neodymium Magnets, NdBFe magnets, NdFeB magnets, NIB magnets, Super Strength magnets and Rare Earth magnets (please note that SmCo is also called a Rare Earth magnet). NdFeB is called a Rare Earth magnet because the Neodymium is a Rare Earth element, having a value of 60 on the Periodic Table. For note, there is nothing rare about Rare Earth magnets – the required elements are readily available and the NdFeB magnets are produced in several hundreds of tonnes each year.

The Neodymium Iron Boron magnets (NdFeB magnets) were developed just over 25 years ago and were first commercially available in 1984. Neodymium magnets were initially developed for voice coil motors in computer hard disk drives and this market still accounts for over 50 percent of all Neodymium magnets produced. Other applications include high performance motors, brushless DC motors, generators, magnetic separation, magnetic resonance imaging, sensors and loudspeakers. They are becoming increasingly popular across a wide range of novelty products such as fridge magnets and all kinds of magnetically attachable gadgets for retail markets.

The NdFeB (NIB) magnets, in disc and ring forms, are usually axially magnetised (the round ends are the magnet poles). Diametrically magnetised discs and rings can be produced upon request (looking at the circular end face, the magnetism runs from the 12 o’clock position to the 6 o’clock position in diametrically magnetised magnets). Likewise, the rectangular blocks can be specially produced to be magnetised in any of the three axes (the magnets cannot be re-magnetised in another axis due to the method of production – the sintered NdFeB is anisotropic). Arcs, trapezoids and other shapes can generally also be produced. Bespoke Directions of Magnetisation within the magnet shape may also be possible (subject to confirmation) e.g. for Halbach Array assemblies.

If you require a bespoke/custom Neodymium Iron Boron (NdFeB, NIB, Neodymium, Neo) magnet or magnetic assembly, Technical Support or our NdFeB Technical Data Sheet, please contact us. And please feel free to browse our NdFeB-Info web site (logo link to the bottom left of this page) for addistional technical information on Neodymium Magnets.

Buy strong magnets online!

We offer an amazing range of magnets in many different shapes and sizes, including:

- Alnico Magnets (AlNiCo)

- Neodymium Magnets (Rare Earth)

- Samarium Cobalt Magnets (SmCo)

- Ceramic Magnets (Ferrite)

- Magnetic Assemblies, Magnetic Strips, Magnetic Tape, Magnetic Labels

- Office Magnets, Whiteboard Magnets

- Magnetic Tools

... and much more.

Strong Magnets (Rare Earth Magnets) and Magnet Material

Magnosphere stocks alnico magnets, bonded magnets, ceramic (ferrite) magnets, flexible rubber magnets, neodymium iron boron (NdFeb) magnets and samarium cobalt magnets along with magnetic material assemblies for fabrication and distribution. Many standard magnetic alloy materials, grades, and geometries (shapes) are available for immediate use. Magnosphere will also fabricate from inventoried permanent magnet materials to your specific requirements.

- AlNiCo, is a ferroalloy with three main components: Al, Ni and Co. It has high curie temperature, is made by casting or sintering process. It has a good corrosion resistance and better physical properties than ferrite.

- Neodymium magnet, is the most powerful permanent magnet. It is widely used in all kinds of motors, electronic component, automatic equipment, new energy vehicle, artificial intelligence, mobile phone and medical device, etc.

- SmCo Magnet, It is also a rare earth magnet, whose strength is second only to NdFeB. Because of high temperature resistance and good corrosion resistance, SmCo is used in electroacoustic devices, motors, measuring instruments, microwave devices, machinery, sensors.

- Magnetic assembly, is assembled with various magnets (NdFeB, SmCo, AlNiCo or other magnets) and metal or plastic products through welding, viscose, stamping, injection molding, pressing, drilling, laminating or other processes, to meet customers’ applications and to reduce production costs. A magnetic assembly incorporates magnet alloy and non-magnet material. Magnet alloy is very hard and even simple features are difficult to incorporate into the alloy. Mounting and application specific features are easily incorporated into the non-magnetic materials, which usually form the housing or magnetic circuit elements. The non-magnet elements will also buffer the brittle magnet material from mechanical stress and increase the overall magnetic strength of the magnet alloy. Diversity exists between the varieties of magnetic alloy materials and grades. Each permanent magnetic material has unique advantages and disadvantages. We suggest that you contact our customer support team so your application can be reviewed. We will then be able to select appropriate magnetic material for your application.

A brief description of commercially available magnetic materials is listed below. A more rigorous explanation and technical characteristics of the various magnetic alloy materials are available on their individual pages.

Pemanent magnet comparison charts Click here to view

Alnico Magnets

Alnico magnets are used primarily in technical applications, where temperature stability is critical. Characteristics: Excellent for high temperature applications up to 1,000°F, high residual induction, and corrosion resistant. Cast alnico magnets can also be produced in relatively complex shapes. Sizes and Shapes: Discs, Rods, bars, and horseshoes. Applications: Commonly used in Meters, and for specialized holding, high-temperature applications. Alnico magnet alloy is largely comprised of Aluminum, Iron, Cobalt and Nickel. Alnico is a moderately expensive magnet material because of the Cobalt and Nickel content. Alnico magnet alloy has high maximum operating temperature and very good corrosion resistance. Magnets made with this alloy are available in a variety of grades and dimensions and are usually cast and finish ground to size. Alnico magnet material is an older technology and it has a rather low Energy Product (BHmax). Alnico magnet alloy is now mainly used in military, aerospace, older proprietary designs and in applications where the magnet will be exposed to elevated temperatures.

- What are the main characteristics of alnico magnets? Alnico magnets offer high magnetic strength, energies but low coercivities. They are less brittle than Rare Earth magnets, are highly resistant to corrosion, have excellent temperature stability and can be used at very high temperatures. Manufactured through either a casting or sintering process, they can be made into complex shapes (such as horseshoe shapes) that are not possible with other magnet materials.

- What grades & shapes are available for alnico magnets? Grades 5 and 8 are the most commonly used Alnico grades. Non-standard shapes can be custom fabricated to blueprint specifications from raw stock in sintered, or cast forms, & we can custom manufacture virtually any shape & size to meet your specialty requirements. Send us a request for quote, and we'll work with you to determine the most economical way to manufacture your specialty project.

- Are there machining constraints for alnico magnets? Alnico magnets are hard and brittle, and prone to chipping & cracking. They require very careful machining & it is not generally recommended that these materials be used for structural or decorative purposes. Machining or drilling cannot be accomplished by ordinary methods. Cutting & grinding should be done prior to magnetizing. Holes must be made by EDM methods. We are fully equipped to machine these materials to your blueprint specifications.

- What are some common applications for alnico magnets? Instrumentation, meters, microwave devices, actuators, holding devices, sensors, are among the most common applications for Alnico magnets. (top)

- Do alnico magnets require surface treatments? Alnico magnets do not typically require a protective coating or plating since they exhibit excellent resistance to corrosion.

- What are some safety precautions that should be taken into consideration when working with alnico magnets? Special care should be taken to assure that these magnets are not subjected to adverse repelling fields, since these could partially demagnetize the magnets. If Alnicos are partially demagnetized, they may be easily re-magnetized.

- What is a permanent magnet? Permanent magnets represent the majority of magnetic materials available today. A permanent magnet is made from ferromagnetic materials, which have magnetic fields that do not turn on and off like electromagnets. We carry a large stock inventory of permanent magnets; neodymium, alnico, ceramic (ferrite) and samarium cobalt, in a wide range of sizes, shapes and grades.

Rare Earth Magnets

Samarium Cobalt Magnets (SmCo) and Neodymium Iron Boron Magnets (NdFeB) are called Rare Earth Magnets because Neodymium and Samarium are found in the rare earth elements on the periodic table. Both Samarium Cobalt and Neodymium magnet alloys are powdered metals which are compacted in the presence of a strong magnetic field and are then sintered.

Neodymium Magnets (Rare Earth)

(NdFeB) Neodymium, a rare earth magnet, is made up of Neodymium Iron and Boron and is moderate in price. With poor corrosion resistance, a neodymium iron boron magnet is usually plated or coated (Examples: Nickel Plated, Epoxy Coated, Parylene Coated). Neodymium magnets are offered in a range of operating temperatures depending on your application (80°C to 200°C). Premium Neodymium magnetic materials capable of operating above 120°C can become quite expensive. This permanent super magnetic material has many intellectual property rights associated with it and there are a limited number of licensed manufacturers in the world. Many infringing manufacturers from the Pacific-rim dump subpar magnetic material into the Western markets. This magnetic material is extremely powerful and it has allowed for the downsizing of many products from HDD (Hard Disc Drives) and motors to novelties and audio devices. Neodymium permanent magnets usually offer the best value when comparing price and performance.

- What is a neodymium magnet? Neodymium magnets are strong permanent magnets, and part of the rare-earth magnet family. They are also referred to NdFeB magnets or NIB, as they are composed mainly of Neodymium (ND), Iron (Fe) and Boron (B).

- Why are neodymium magnets so strong? Neodymium magnets are considered strong because they resist demagnetization and have a high saturation magnetization. Although neodymium magnets are more costly than ceramic magnets, these super strong magnets pack a powerful punch! With neodymium magnets, you can use a smaller sized magnet to achieve the same objective. This can potentially lead to a lower overall cost, as the size of the entire device can shrink.

- How long do neodymium magnets last? Neodymium magnets will likely lose less than approximately 1% of their flux density over a 100-year period if their physical properties remain intact.

- What are the main characteristics of neodymium magnets? Neodymium magnets are far less subject to cracking & chipping and less costly than other rare-earth magnetic material such as Samarium Cobalt ("SmCo"). They are however, more sensitive to temperature. For applications where this is critical, SmCo may be the better choice, since its magnetic properties are very stable at elevated temperatures.

- What grades & shapes are available for neodymium magnets? Grades 30-52 of Neodymium magnets are available in disc, rectangle, square and rod shapes, and can be custom manufactured to meet your specialty requirements.

- What are some common applications for neodymium magnets? Neodymium Magnets are typically used in audio equipment (microphones, headphones, and loudspeakers) hard disk drives, pumps, bearings, MRI scanners, electric vehicles, wind generators, high performance motors, actuators, magnetic therapy, anti-lock braking systems, levitation devices, door latches, model making, arts & crafts, home improvement (DIY-fixing furniture, hanging pictures etc.) POP displays & more.

- What are the best temperatures to use for neodymium magnets? Neodymium magnets should not be used in temperatures above 130° C(240° F) without careful magnetic circuit design. Please contact us to discuss your application with our engineers if you plan on using these magnets above this temperature.

- Do neodymium magnets require surface treatments? Neodymium magnets that are not protected with a surface coating (such as plating) may rust in humid conditions. (top)

- What common bonding applications are used for neodymium magnets? Neodymium magnets are often assembled into products using “super glues” such as Loctite 325. As with all bonding applications, please ensure that bonding surfaces are clean and dry (prior to bonding) for best results.

- What is a permanent magnet? Permanent magnets represent the majority of magnetic materials available today. A permanent magnet is made from ferromagnetic materials, which have magnetic fields that do not turn on and off like electromagnets. We carry a large inventory of permanent magnets; neodymium, alnico, ceramic (ferrite) and samarium cobalt, in a wide variety of shapes, sizes and grades.

- What is a rare-earth magnet? Rare-earth magnets are the strongest type of permanent magnets available today, and produce significantly stronger magnetic fields than ceramic (ferrite) or alnico magnets. There are two types of rare-earth magnets; neodymium and samarium cobalt, both of which are available for on-line purchase. Click here to learn more information about magnetic materials.

- How are magnets rated? Magnets are typically rated by their residual induction, coercive force & maximum energy product. This refers to the maximum strength that the magnetic material can be magnetized to.

- What does "approximate pull Info" mean? The approximate pull info listed for Neodymium magnets are for reference only. These values are calculated under the assumption that the magnet will be attached to a flat, ground 1/2" thick mild steel plate. coatings, rust, rough surfaces, and certain environmental conditions can significantly reduce the pull force. Please be sure to test the actual pull in your actual application. For critical applications, it is suggested that the pull be de-rated by a factor of 2 or more, depending on the severity of a potential failure.

- What safety precautions should be taken into consideration when working with neodymium magnets? Neodymium magnets are hard, fairly brittle, and high in magnetic strength. They can snap together with great force, so please ensure that all personnel handling these magnets are aware to handle them carefully in order to avoid injuries. They can also chip or break if dropped or if snapped together, so please take special care when handling these powerful magnets!

Samarium Cobalt Magnets (Rare Earth)

Samarium Cobalt, another rare earth magnet, is made up largely Cobalt and Samarium and is the most expensive magnetic material to manufacture and to fabricate. Most of the cost is due to the high Cobalt content and the brittle nature of the Samarium alloy. This permanent magnetic material offers high resistance to corrosion and can withstand high operating temperatures, up to 350°C. Samarium Cobalt magnetic materials are used extensively in the aerospace market or in areas of industry where performance is the priority concern and cost is secondary. Samarium Cobalt is the second most powerful magnetic material and exhibits excellent resistance to demagnetization.

- What are the main characteristics of samarium cobalt magnets? Samarium Cobalt Magnets exhibit excellent corrosion resistance, and do not need to be protected for corrosion. SmCo magnets also offer high-resistance to demagnetization.

- What are the best temperatures to use for samarium cobalt magnets? SmCo magnets are very temperature stable - their properties stay within a very narrow range up to about 300° C (570° F).

- What are some common applications used for samarium cobalt magnets? SmCo’s magnetic characteristics are ideal in applications for the marine, automotive, aerospace, medical, military and industrial automation industries where high- temperature performance is critical. They are commonly used in motors, machinery, pumps, medical devices, magnetic couplings, magnetic separators and more. (top)

- What grades & shapes are available for SmCo magnets? SmCo magnets are available in a number of different grades that span a wide range of properties and application requirements. We currently stock SmCo disc magnets in grades 18 and 26, available in a wide range of sizes.

- What are recommended bonding applications for SmCo magnets? SmCo magnets are often assembled into products using "superglues" such as Loctite 325. It's best to avoid placing mechanical stress on this material, and always ensure that bonding surfaces are clean and dry prior to bonding.

- What are some safety precautions that should be taken into consideration when working with samarium cobalt magnets? SmCo magnets are hard, very brittle, and high in magnetic strength. They can snap together with great force, so please ensure that all personnel handling these magnets are aware to handle them carefully to avoid injuries. They can also chip or break if dropped or snapped together, so please take special care when handling these powerful magnets!

- What is a permanent magnet? Permanent magnets represent the majority of magnetic materials available today. A permanent magnet is made from ferromagnetic materials, which have magnetic fields that do not turn on and off like electromagnets. We carry a large inventory of permanent magnets; neodymium, alnico, ceramic (ferrite) and samarium cobalt, in a wide range of shapes, sizes and grades. (top)

- What is a rare-earth magnet?Rare-earth magnets are the strongest type of permanent magnets available today. Rare earth magnets product significantly stronger magnetic fields than ceramic (ferrite) or alnico magnets. The two types of rare-earth magnets are neodymium and samarium cobalt magnets, both of which are available for on-line purchase.

- How are magnets rated? Magnets are typically rated by their residual induction, coercive force & maximum energy product. This refers to the maximum strength that the magnetic material can be magnetized to.

Ceramic Magnets (Ferrite)

Ceramic magnet material (Ferrite) is Strontium Ferrite. Ceramic magnets are one of the most cost-effective magnetic materials manufactured. The low cost is due to the cheap, abundant, and non-strategic raw materials used in manufacturing this alloy. Permanent Ceramic magnets lend themselves to large production runs. Ceramic magnet material (Ferrite) has a fair to good resistance to corrosion and can operate in moderate heat. The majority of the worlds Ceramic magnetic material comes from China because of the alloys commodity nature and the high tooling costs found in the west. Ceramic (Ferrite) magnets have a low Energy Product and are usually used in an assembly containing mild steel.

- What are the main characteristics for ceramic magnets? Ceramic magnets are medium in magnetic strength, and can be used at fairly high temperatures. They are low cost, making them ideal for applications such as automotive sensors, magnetic separators, craft projects, badge holders, latches, display boards, science projects, toys, games & more.

- What grades & shapes are available for ceramic magnets? Grades 5 (most commonly used) through 8 are available in disc, block (rectangle & square) and ring shapes, and can be custom manufactured to meet your specialty requirements.

- What are the temperature constraints for ceramic magnets? Ceramic magnets can be used at fairly high temperatures, although their magnetic properties drop with temperature. At 175°C (350° F), approximately 75% of their room temperature magnetic properties are retained.

- How are magnets rated? Magnets are typically rated by their residual induction, coercive force & maximum energy product. Click here for more details (section 4.0). This refers to the maximum strength that the magnetic material can be magnetized to.

- What are some common applications for ceramic magnets? Common applications for ceramic magnets include raft projects, refrigerator magnets, badge holders, latches, display boards, loudspeakers, security systems, motors, generators & alternators, lifting magnets, eddy current devices, brakes, clamps, switches & relays, sweeper magnets, science projects, toys, games, motors, magnetic couplings, POP displays, advertising giveaways, promotional items, novelties & more.

- Are there machining constraints for ceramic magnets? Ceramic magnets require special machining techniques, and should be machined in an “un-magnetized” state. We are fully equipped to machine these materials to your specifications, just let us know what you are looking for by sending us a special request.

- Are surface treatments required for ceramic magnets? Ceramic magnets do not need to be protected for surface rust. A thin film of magnet powder on the surface is common.

- What are some bonding applications for ceramic magnets? Ceramic magnets are often assembled into products using "superglues" such as Loctite 325 or other epoxies. Please always ensure that bonding surfaces are clean and dry prior to bonding.

- What safety precautions should be taken into consideration when working with ceramic magnets? Ceramic Magnets are hard & brittle, and they can chip or break if dropped or snapped together, so please take special care when handling these magnets!

Bonded Magnets

Bonded magnet materials can be made from Ceramic, NdFeB, or SmCo powders which are combined with a variety of plastic binders (Matrix). They can be either Injection Molded or Compression Bonded into complex magnet shapes with finished dimensions. Bonded magnet materials have a moderate resistance to corrosion and a low tolerance to heat because of the binder material. Bonded magnets are commonly used in automotive parts because they lend themselves to large production quantities and complex shapes can be produced at a low cost.

How to Safely Seperate Your Magnosphere Magnets?

CORRECT

- 1. Slide one magnet off the top of the stack.

- 2. Once off thestack,carefully start lifting the magnet.

- 3. Lift the magnet to free it from the stack.

INCORRECT

- DO NOT attempt to pull, lift, or pry amagnet from the stack before sliding it to the side.

- DO NOT throw away the white storage spacers.

- DO NOT allow the magnets to snap to each other or any magnetic surface. doing so may cause magnets to break!

Who supplies high quality Supermagnets, Magnets and Magnet Material?

Magnosphere produces magnets at great prices, produced and delivered on time for all areas of industry, automotive, aerospace, electronics as well as in the design sector, trade fair construction, offices and for the home.

We are an ISO certified shop and carry the Trusted Shops seal. We have successfully completed more than 200,000 orders and offer our ever-growing customer base 24/7 customer service.

All items are available for immediate delivery in large numbers with daily dispatch. Our selection is your win! Thousands of satisfied customers! Buy from a company with the highest quality standards and customer service with flexible and diverse payment options and conditions.

We can also custom manufacture these to fit your exact specifications using our in-house global manufacturing facilities and team of experienced engineers. Need high quantities of magnets at the lowest and fairest price possible? Just let us know what you are looking for and contact our Customer Care Team by sending us a request for quote! We'll work with you to determine the most economical way of providing you with what you need.

Trust in our experience and convince yourself of our service and our products and we look forward to welcoming you to our magnet shop at Magnosphere. You are welcome to contact us by eMail: info(at)magnosphere.co.uk. Available 24/7 x 365 and we are also there for you on public holidays! Or just give us a call.

ROHS-Directive

Magnosphere conforms to the RoHs directive and the Reach and PFOS regulations. Directive 2002/96 / EC of the European Parliament and of the Council, of January 27, 2003, on waste electrical and electronic equipment (WEEE).

We are very proud to offer excellent customer service. We know that without our clients, we would not be here. If you have any questions about your order or something else, please call or email us! 24 / 7 x 365 Including holiday periods! Our customer service team is available to help you!

- Hotline: +49 (0) 2241 959450

- Telefax: +49.2241.9594520

- eMail: info@magnosphere.co.uk